AR/FR PPE is put to the test in harsh environments and through repeated launderings. While some wear and tear is to be expected, color fading doesn’t have to be accepted anymore. While you may not give a second thought about the “science of fabric,” consider how important it is to preserve the exact color of your corporate brand on what your workers wear. Innovations in textile science over the years have created more advanced options, including solution-dyed fabrics which have their color and protection applied from the inside out.

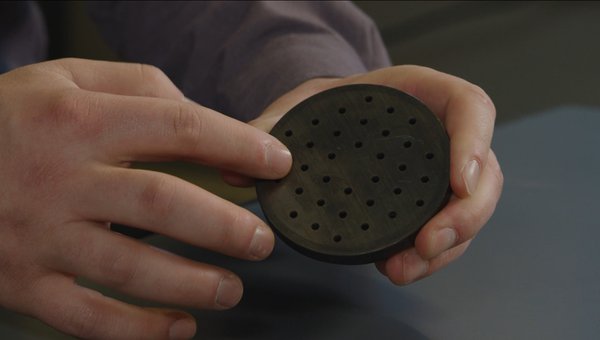

Solution-dyed fabrics are woven using fibers that have had their pigment and other properties added to the polymer before it is extruded through a spinneret, a device very similar to a showerhead.

So once the fibers leave the spinneret, they have the protective properties and color pigments embedded at their core. This means that fabric woven from these fibers will also have color and protection inherent in the fibers, so the protective properties won’t wash away and color durability is significantly improved over the life of the garment.

In comparison, fabrics that are piece-dyed have the color pigment and the protective properties added after the fabric is woven. Garments made from these treated fabrics are traditionally less colorfast and less durable as a result.

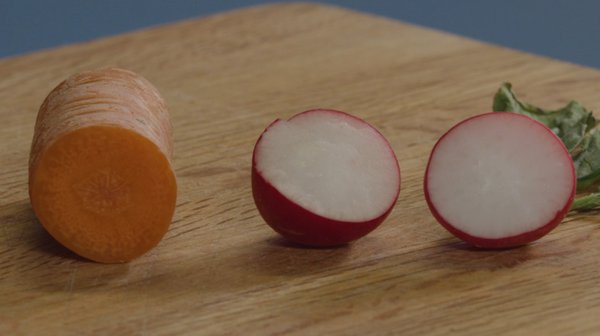

To help picture these differences, you can compare a carrot and a radish. If you cut a carrot in half, the vegetable is orange all the way through, inside and out. That is pretty indicative of a solution-dyed fiber. A radish on the other hand only has color on the outside, just like piece-dyed garments or piece-dyed yarns. There is no fixed color on the inside, therefore, one can expect decreased color fastness over time.

These differences are especially easy to see when it comes to laundering. When washed, garments made with solution-dyed fabrics do not visibly bleed onto other items they are washed with. On the other hand, when washing a piece-dyed garment there is a chance that the pigment could transfer over to other garments being washed alongside it. Some of this bleeding can be avoided by washing single-color loads, but enhanced visibility garments or garments made with multiple colors of fabric are still likely to be affected.

Solution-dyed fabrics have a few other benefits when being compared to piece-dyed fabric as well, such as:

- Fade resistance

- Stain resistance

- UV resistance

Solution-dyed fabrics are also better for the environment, saving not only water but energy as well since it does not call for physical liquid rinsing or dyeing.

There are a lot of factors to consider when choosing AR/FR garments for your workers. When evaluating the durability of your options, find out whether the fabrics used are solution-dyed, inherent fabrics or piece-dyed, treated fabrics. Solution-dyed fabrics offer superior color durability and protection after heavy use and repeated launderings, meaning your workers’ PPE will look better and last longer.

To learn more and see the difference, watch our Solution-Dyed series on The FRontlines: https://bit.ly/3dxYAJm.